SPONSORED CONTENT

Across Australia’s electricity, gas and water networks, meter security is a critical operational and compliance consideration. Meter seals form the first line of defence against unauthorised access, providing visible, tamper-evident protection for meters, enclosures, switchboards and associated infrastructure.

Choosing the right sealing solution and managing it correctly plays an important role in maintaining asset integrity, meeting regulatory requirements and supporting accountability across utility networks.

Harcor, Australia’s first dedicated security seal supplier, has supported utilities and contractors for decades with proven meter seals, sealing wire, presses and identification systems designed specifically for real-world field conditions.

What meter seals do and why selection matters

Meter seals are designed to deter and reveal tampering, but not all seals are suited to every application. The right seal must strike a balance between:

- Ease and speed of installation

- Durability in harsh outdoor environments

- Compatibility with sealing wire or presses

- The required level of deterrence and traceability

- Regulatory or contractual compliance obligations.

By selecting compatible combinations of seal, wire and press, utilities can standardise field practices, reduce installation time and improve consistency across teams and locations.

Common meter seals used in utility applications

Tool-Less Roto Meter Seal (SCEC Approved)

The Tool-Less Roto Meter Seal is a high-security wire seal designed for fast installation without specialised tools. Manufactured from durable acrylic, it features unique sequential numbering, a large visible flag, and a laser-etched insert that mirrors the final digits of the serial number, improving traceability in the field.

This seal holds current SCEC approval, confirming its suitability for government and other sensitive applications. It is commonly used on meters, cabinets, switchboards and valves.

The Tool-Less Roto Seal can be paired with stainless steel wire rolls cut to length, or pre-cut wire options for consistent installation.

Why utilities choose it: SCEC approval, strong tamper evidence and a simple, repeatable application process that supports consistent field practice.

Tool-Less Meter Seal with Sealing Wire

This single-component seal includes pre-attached nylon-coated stainless steel wire, reducing handling time and simplifying installation. Supplied with unique sequential numbering and convenient multi-seal mats, it is well suited to high-frequency sealing applications.

Typical uses include electricity, gas and water meters, fuel tanks, petrol pumps, drums and scales, where fast deployment and clear tamper evidence are essential.

Operational advantage: Having the sealing wire already attached delivers a genuine time saving, particularly for contractors completing repetitive sealing tasks in the field.

Serial number control: Supporting accountability and compliance

Serial number management is often overlooked until it becomes critical. In the event of a dispute, audit or investigation, utilities may need to demonstrate that a seal number was issued exclusively to their organisation.

Harcor’s Exact & Track system provides controlled, verifiable serial number management, preventing duplication and maintaining clear records of issuance. Developed in accordance with ISO 9001:2015, the system supports audit requirements and strengthens accountability across metering operations.

Harcor Energy Seal (Press-Crimp Slim Tail Seal)

The Harcor Energy Seal is a slim-tail, press-crimp seal designed for modern utility enclosures, including electricity meters, circuit breakers, time switches and safety switches. It is applied using the Harcor Sealing Press and supplied in mats for efficient handling.

Optional custom character marking can be added using engraved dies, allowing seals to be permanently marked with technician IDs or business initials.

Harmet Meter Seal and Harmet Tail System

The Harmet Meter Seal is a compact polypropylene seal used with wire or the Harmet Tail, then crimped using the Harcor Sealing Press. Widely adopted as an alternative to traditional lead seals, it offers a reliable, easy-to-apply solution with embossed identification options for added security. The Harmet Tail is specifically engineered to simplify insertion and achieve a secure crimp, improving consistency in field applications.

Metal Ferrule Seal (Press-Crimp Metal Seal)

The metal ferrule seal is a compact copper/tin seal crimped with the Harcor Sealing Press and paired with pre-cut stainless steel wire. It is commonly selected for harsh environments where a metal seal body and metal wire are preferred for durability and inspection clarity.

One press, multiple applications

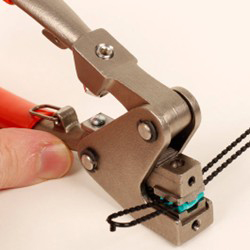

Harcor’s Stainless Steel Meter Seal Press is purpose-built for utility sealing applications. Featuring interchangeable dies, it can be used across multiple seal types, including Harcor Energy Seals, Harmet Seals and Metal Ferrules.

The press also supports engraved dies to permanently identify the sealing authority—such as technician IDs or business initials—providing a clear alternative to serialised seals where individual numbering is not required.

Identification and compliance

Utilities apply different identification approaches depending on operational requirements. Some workflows rely on serialised seals to support auditing and traceability, while others use press-marked identification to clearly identify who carried out the sealing task without the need for individual serial tracking.

Local expertise backed by a comprehensive range

Harcor’s utility range includes tool-less wire seals, press-crimp slim tail seals, Harmet systems, metal ferrules, sealing wire, presses and engraving services. As a long-standing supplier to utilities across Australia, Harcor supports product selection with practical, application-based advice.

For assistance with meter sealing or broader utility sealing requirements, Harcor works directly with utilities and contractors to recommend solutions that meet operational, compliance and environmental needs.

Click here for more information.